Sandblasting is a powerful surface preparation method that involves propelling abrasive particles such as sand, glass beads, or aluminum oxide at high velocity onto a material. This process removes contaminants like rust, paint, and scale, and is ideal for cleaning and prepping surfaces for coatings or finishes.

When it comes to stainless steel, sandblasting helps improve surface texture, enhance appearance, and increase adhesion for subsequent coatings making it an essential technique across various industries.

Stainless steel is a corrosion-resistant alloy primarily made of iron, chromium, and nickel. Thanks to the chromium content, it forms a protective oxide layer that resists rust and staining.

While it’s commonly used in kitchens for cookware and utensils, stainless steel also plays a crucial role in industries like aerospace, automotive, construction, and medical equipment due to its strength, hygiene, and resistance to corrosion.

Yes, stainless steel can be sandblasted effectively—but with the right technique and abrasive media. Since stainless steel is a more sensitive and high-value material, improper blasting can damage its surface permanently.

When performed correctly, sandblasting can:

The final result depends largely on the abrasive material used, pressure settings, and the size of particles.

Sandblasting cleans and roughens the surface, enhancing the adhesion of paints, coatings, and adhesives for longer-lasting results.

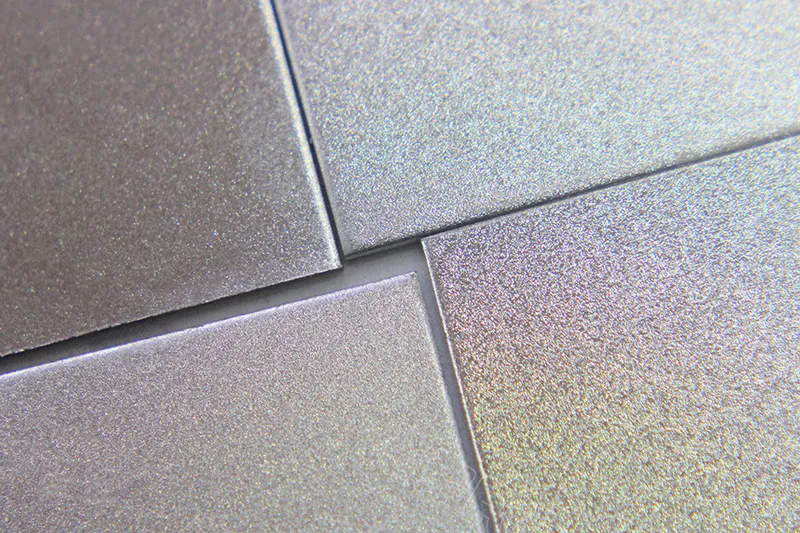

It creates a uniform, non-reflective matte or satin finish, ideal for decorative applications. This treatment masks blemishes, fingerprints, and scratches.

By improving surface adhesion and removing corrosion, sandblasting increases the overall lifespan of stainless steel components.

The process is used across multiple industries architecture, automotive, marine, interior design, and manufacturing for both functional and decorative purposes.

Sandblasted finishes are low-glare and easier to maintain than polished surfaces, requiring only occasional cleaning with mild detergents.

1. Safety First

Ensure maximum protection by wearing the appropriate safety gear, including gloves, goggles, a respirator, and protective clothing. This is crucial to shield yourself from airborne particles and abrasive materials during the sandblasting process.

2. Surface Preparation

Before starting the sandblasting, it’s essential to thoroughly clean the stainless steel surface to eliminate any dirt, oil, grease, or debris. After cleaning, make sure the surface is completely dry to ensure proper adhesion of the abrasive media.

3. Set Up Equipment

Properly connect all necessary equipment, including the air compressor, blasting pot, and nozzle. Adjust the air pressure according to the abrasive material you’re using and the type of surface you’re working on to ensure optimal blasting performance.

4. Blasting Process

When sandblasting, use steady, back-and-forth motions to ensure the abrasive media covers the surface evenly. Keep a consistent distance from the surface to maintain uniform texture, and continuously monitor the blasting process. Make adjustments as needed to achieve the desired finish.

5. Post-Blasting

After sandblasting, carefully blow off or brush away any residual abrasive particles left on the surface. For added protection, consider applying a protective coating or passivation treatment to restore the metal’s corrosion resistance and improve its longevity. This helps maintain the material’s appearance and durability over time.

From implantable devices to surgical instruments, electropolishing provides a single-step treatment that delivers biocompatible, ultra-clean, and safe components.

We provide aerospace vendors and OEMs with our signature metal finishing services, enhancing fatigue resistance and ensuring their metal parts withstand long-term stress and corrosion.

We follow industry standards to electropolish pharmaceutical components in compliance with ASTM B912 and ASME BPE, ensuring clean, smooth, corrosion-resistant surfaces free from contaminants.

Corrosion resistance and micro finish improvement are essential for critical automotive parts, making electropolishing an increasingly beneficial option for automakers.

Our metal finishing services enhance corrosion resistance and, through electropolishing, remove the outermost metal layer boosting the durability and lifespan of appliance components.

Electropolishing materials used in this industry help prevent bacterial biofilm buildup and eliminate contaminants like Salmonella. This process ensures the high level of sanitation required by various regulatory agencies.

From robotics to mobile equipment, electropolishing plays a vital role in the hydraulics and pneumatics industry. By preventing premature part failure, it minimizes downtime and extends the lifespan of critical components.

Electropolishing enhances both conductivity and performance in electronic components. It also improves surface finish by up to 50%, eliminating imperfections without compromising the material’s integrity.