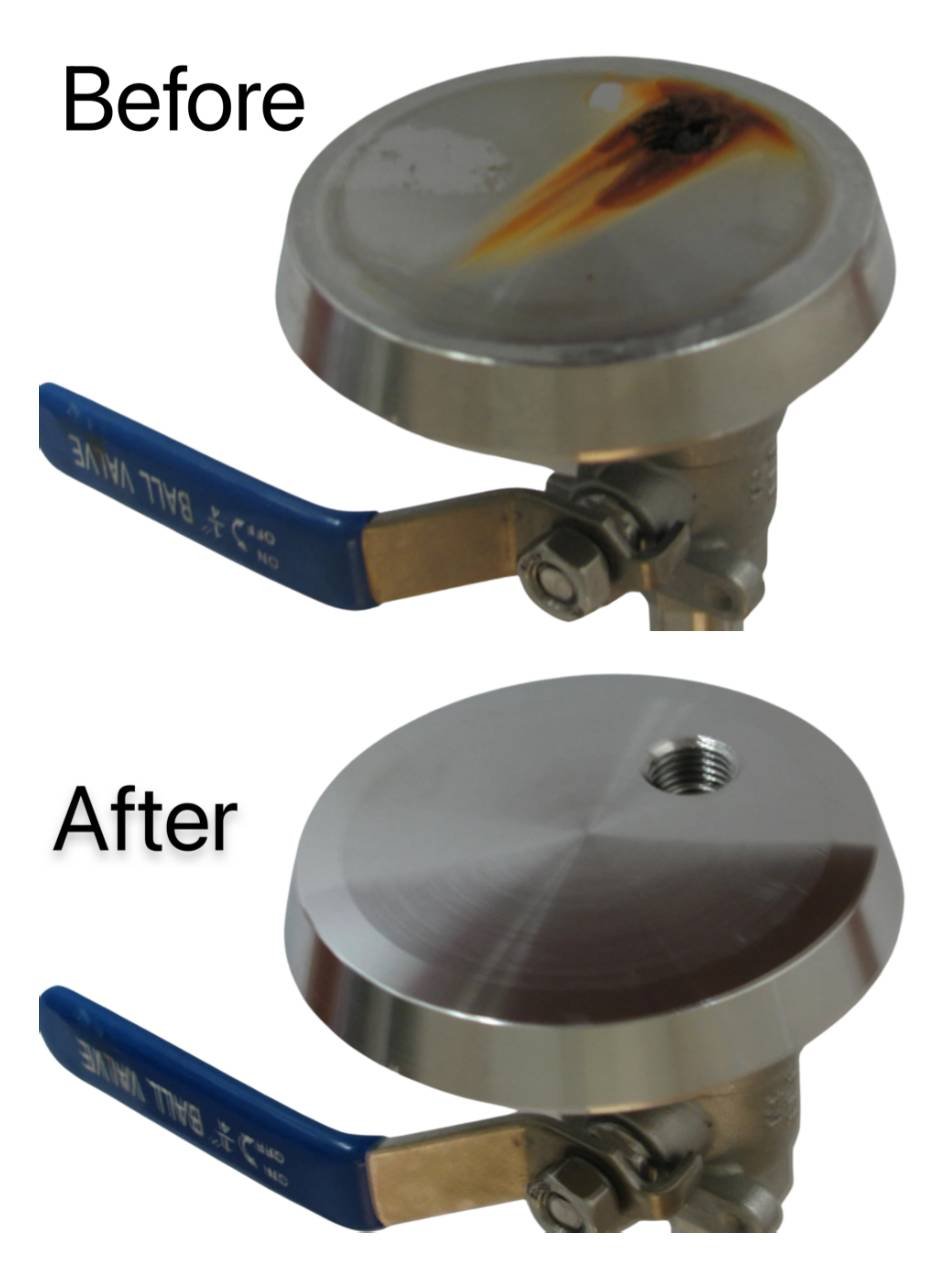

Electropolishing works by selectively removing the outer layer of metal, effectively eliminating deeply embedded contaminants that passivation cannot reach. This makes it ideal for complex components such as machined parts and welded assemblies that typically do not respond well to passivation alone.

Unlike passivation, electropolishing can be used on all stainless steel grades—including 400 series and precipitation-hardened alloys—without risk of distortion, hydrogen embrittlement, or flash attack. The process not only passivates the material but also significantly improves surface finish and corrosion resistance.

From implantable devices to surgical instruments, electropolishing provides a single-step treatment that delivers biocompatible, ultra-clean, and safe components.

We provide aerospace vendors and OEMs with our signature metal finishing services, enhancing fatigue resistance and ensuring their metal parts withstand long-term stress and corrosion.

We follow industry standards to electropolish pharmaceutical components in compliance with ASTM B912 and ASME BPE, ensuring clean, smooth, corrosion-resistant surfaces free from contaminants.

Corrosion resistance and micro finish improvement are essential for critical automotive parts, making electropolishing an increasingly beneficial option for automakers.

Our metal finishing services enhance corrosion resistance and, through electropolishing, remove the outermost metal layer boosting the durability and lifespan of appliance components.

Electropolishing materials used in this industry help prevent bacterial biofilm buildup and eliminate contaminants like Salmonella. This process ensures the high level of sanitation required by various regulatory agencies.

From robotics to mobile equipment, electropolishing plays a vital role in the hydraulics and pneumatics industry. By preventing premature part failure, it minimizes downtime and extends the lifespan of critical components.

Electropolishing enhances both conductivity and performance in electronic components. It also improves surface finish by up to 50%, eliminating imperfections without compromising the material’s integrity.