While passivation helps improve the corrosion resistance of stainless steel, it doesn’t fix everything. After welding or heat treatment, parts can develop discoloration (called heat tint) and surface scale that passivation alone can’t remove.

That’s where pickling comes in a chemical process traditionally used to clean up these imperfections before passivation.

Pickling involves dipping stainless steel parts into a strong acid bath usually made with hydrochloric or sulfuric acid. This treatment removes heat tint, oxide scale, and tiny bits of steel that may be stuck to the surface during manufacturing.

But pickling has its downsides. It’s not very precise, can be hard to control, and often gives uneven results. Over time, the acid gets weaker, which affects how well it works. Plus, there are strict environmental regulations around its use, making it more challenging to handle safely and responsibly.

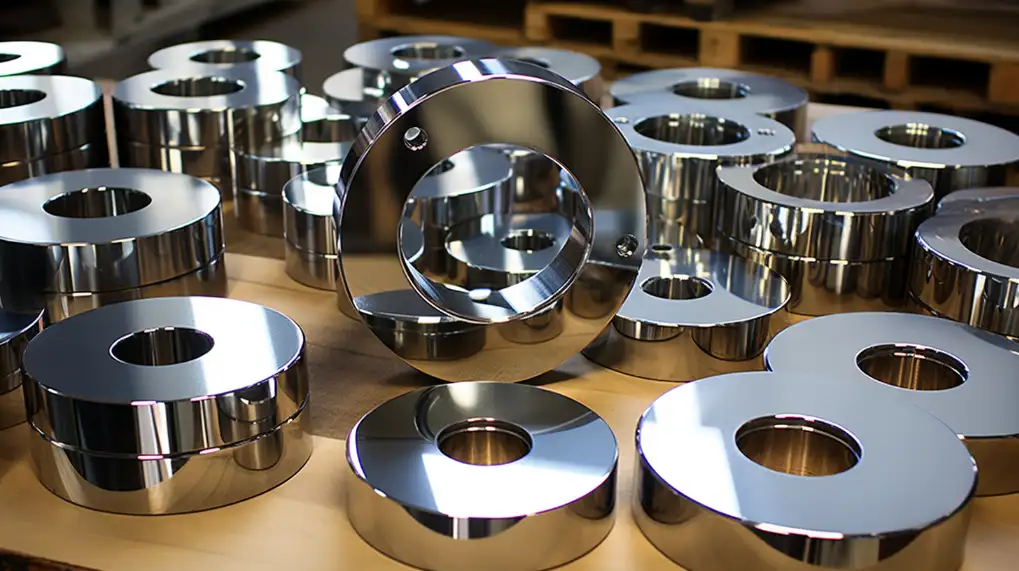

Over time, electropolishing has become the go-to alternative to traditional methods like pickling. It’s a one-step process that removes a very thin, precise layer from the surface of metal parts smoothing out imperfections and leaving them cleaner, stronger, and more resistant to rust and bacteria.

Unlike pickling, electropolishing works on a wide range of metals and specialty alloys and gives a much more consistent, high-quality finish. It not only improves appearance but also boosts performance and cleanliness making it ideal for industries that require precision and hygiene.

From implantable devices to surgical instruments, electropolishing provides a single-step treatment that delivers biocompatible, ultra-clean, and safe components.

We provide aerospace vendors and OEMs with our signature metal finishing services, enhancing fatigue resistance and ensuring their metal parts withstand long-term stress and corrosion.

We follow industry standards to electropolish pharmaceutical components in compliance with ASTM B912 and ASME BPE, ensuring clean, smooth, corrosion-resistant surfaces free from contaminants.

Corrosion resistance and micro finish improvement are essential for critical automotive parts, making electropolishing an increasingly beneficial option for automakers.

Our metal finishing services enhance corrosion resistance and, through electropolishing, remove the outermost metal layer boosting the durability and lifespan of appliance components.

Electropolishing materials used in this industry help prevent bacterial biofilm buildup and eliminate contaminants like Salmonella. This process ensures the high level of sanitation required by various regulatory agencies.

From robotics to mobile equipment, electropolishing plays a vital role in the hydraulics and pneumatics industry. By preventing premature part failure, it minimizes downtime and extends the lifespan of critical components.

Electropolishing enhances both conductivity and performance in electronic components. It also improves surface finish by up to 50%, eliminating imperfections without compromising the material’s integrity.